Having delivered thousands of machines since 1981, the Autofold range has consistently demonstrated its design durability and impressive payback results across the world.

Every Autofold machine is constructed using heavy-duty welded frames, incorporating Bosch Rexroth hydraulics. Our machines also feature a proprietary controller and software that can be tailored to meet specific customer requirements.

The Autofold has a remarkable track record of reliability, even in harsh environments, thanks to its design and manufacturing process that enables it to operate effectively in extreme upper and lower temperatures.

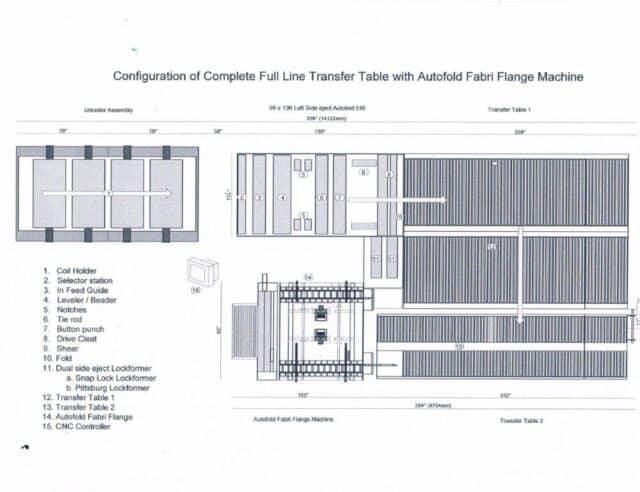

The Transfer line has the advantage over straight lines that cannot do the following actions:

- Drive cleat and tdf can be done on the same machine

- Flat sheet for plasma take off is easily done

- Multiple ducts are on the machine during full production meaning the production rates are higher

- Snaplock and Pittsburgh locks are automatically changed with only software input ,no operator input is required

- Bespoke built to work around your factory flow

Autofold Standard Features

The Autofold fold and Shear Head has 2 blades that are equipped with 4 cutting sides each giving many years of continuous production

The shear operates from the bottom to allow the duct to be wrapped around the fold Beam.

The 7 roll leveller is the drive of the Autofold and is driven direct from the Autofold hydraulic gearbox to eliminate any wear or slack in chains found on other machines.

The leveller and Beader rolls can be operated from either side via direct shaft for added accuracy.

The rolls are s-45 carbon steel machined and ground and are of solid bar type.

No chains that can stretch are used in our levellers.

5 tonne expandable mandrels.

Included with an Autofold are 2 coils.

Options are “A” frame coil holders and “I” beam coils. All spindles are rated for 5 tonnes maximum weight at 1500 wide but can accept smaller widths.

Hydraulic Servo Drive System

All Autofolds use the hydraulic drive system that is controlled by our Autofold “v” system this ensures energy efficient motors coupled with compact hydraulic system fitted inside all machines ,there is no air required on any Autofolds.

Control System

At the heart of the Autofold is the advanced solid state control system which has been continuously developed through the Autofold life.

The controller is based around a single board pc running bespoke software with embedded OS having an intuitive and easy to use control interface, thus making the Autofold easy to learn and operate by multiple employees in the factory environment through a touch screen interface.

The controller consistently monitors machine functions and operations. In the event of a machine fault or incorrect usage or power supply failure the system will give a clear onscreen feedback to the operator.

If the control system is connected via the optional wifi to the customer’s network and then via this to our factory diagnostics team, we can be called on to assist with any questions or data can be extracted and investigated.

All Machine power is fed through the controller via one power source. The Autofold can work from 208v through 480v allowing the Autofold to be installed anywhere in the world .