At the heart of all Autofold machines is an advanced control system, available with various options. This system has been specifically designed for the Autofold machine range, and has been in constant development throughout the 30 year life of the Autofold machines.

The controller is based around a custom single board computer running bespoke software resulting in an intuitive, easy to use, control interface.

Many other machine manufacturers rely on ‘bought in’ control systems, circuit boards, etc. Often trying to use generic machine control packages. This means that they are at the mercy of 3rd party suppliers who may decide to discontinue items, or change functionality without reference to the machine builder. With the Autofold system, a full support and repair service is available for all control systems, regardless of age.

The controller constantly monitors the machine commands and responses. In the event of a machine fault, clear feedback is given to the user.

All machine electrical power is fed through the controller. This means that the Autofold machine requires one 3 phase power supply. There is no requirement for separate motor feeds, or control gear.

The Autofold controller can be configured for input voltages from 208V to 480V. This gives the machine the capability to be installed almost anywhere in the world without modification.

Control system features vary with machine type. They are too numerous to list in full, but include:

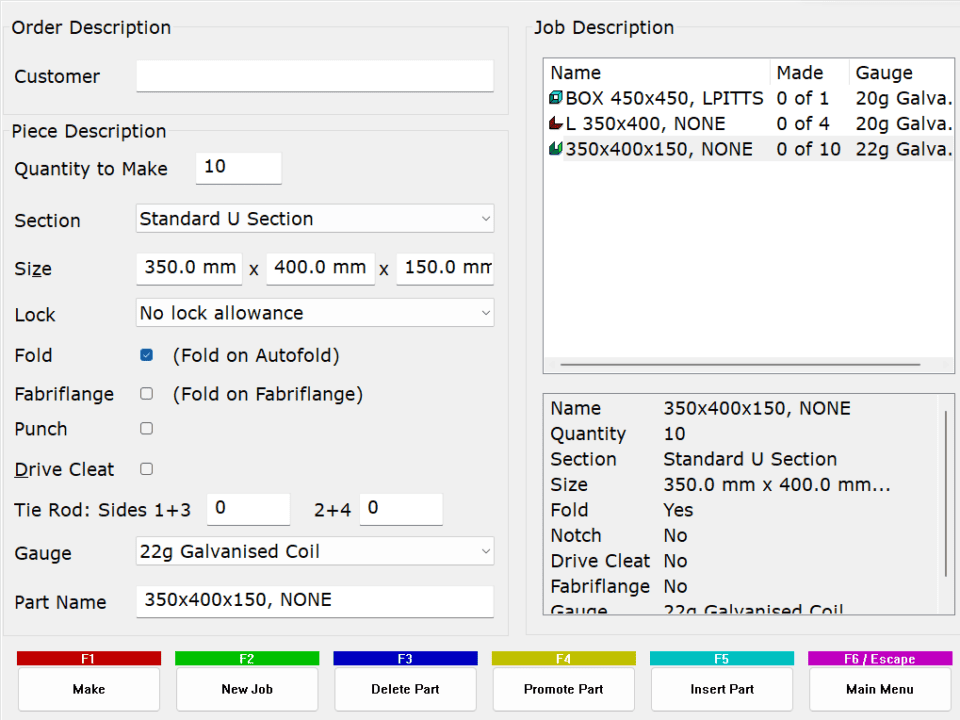

- Rapid one-off part production using Make Quick feature

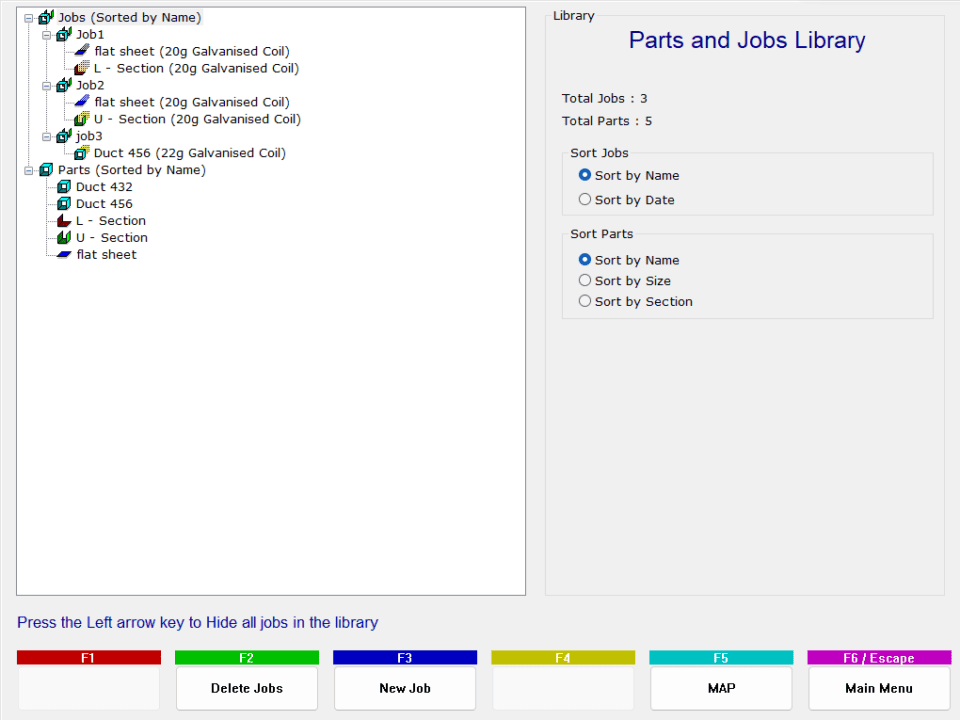

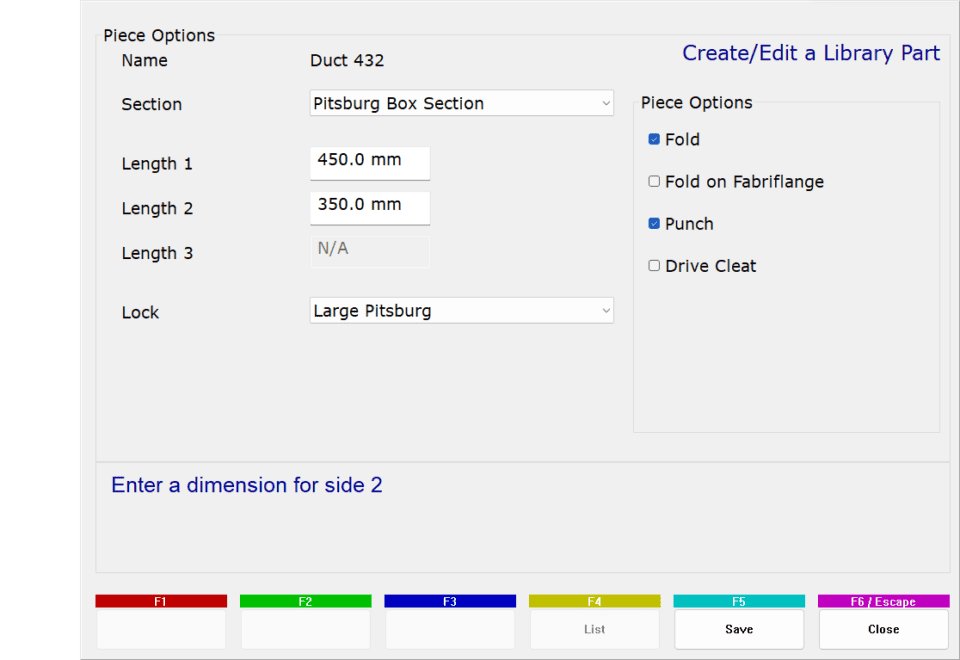

- Library of user defined parts locks and gauges

- Constant machine status and mains supply monitoring

- Inbuilt diagnostics

- Optional remote link for CAM download

- Optional wireless connection to factory network (then internet) for…

- Remote diagnostics

- Software update

- Data backup

Controller Retrofit

There are many older Autofold machines, still in service, that can benefit from the numerous features and improvements of the current Autofold control system.

We can supply either the basic iFold control system, or the full Console control system, as used on the more complex machines.

The new control system can be fitted to any age of Autofold machine. The new control system supports both variable and fixed (as used in old machines) rate flow systems. If running an older fixed rate machine, the hydraulic pack can also be upgraded to variable flow by an Engel technician, giving improved machine performance.

The replacement control systems are often built with minor changes to machine wiring looms for compatibility with older machines. They can be provided for installation by the end user, local agent, or Engel Europa.

When fitting a new control system, it is beneficial to also take advantage of a concurrent site visit by Engel Europa, or one of their representative agents, to service the mechanical aspects of your machine.

Please note Engel Europa are not prepared to supply the control system for use on other manufacturer’s machines.